As cities evolve, the bollard industry will continue to innovate, ensuring safety and style go hand in hand.

The Manufacturing of Bollards: Crafting Safety and Style for Modern Spaces

Introduction

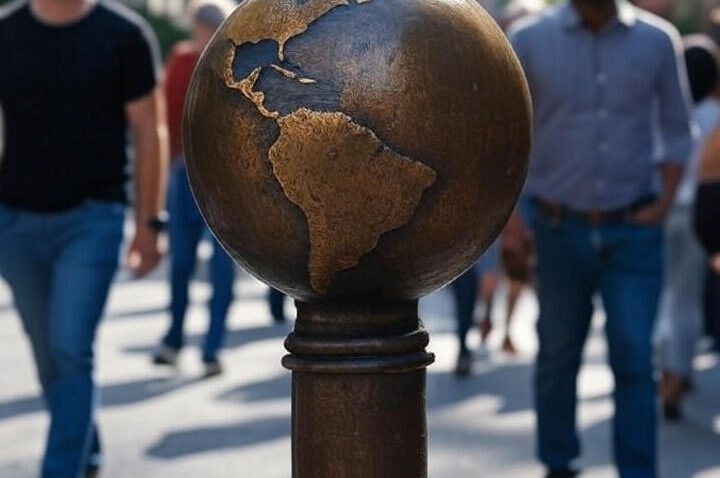

Bollards, the sturdy vertical posts that safeguard public and private spaces, are more than simple barriers—they are precision-engineered products designed for durability, security, and aesthetics. From fixed pedestrian guides to high-security pneumatic systems, the manufacturing of bollards involves advanced materials, innovative techniques, and rigorous testing to meet diverse urban needs. This article explores the manufacturing process of bollards, tracing the journey from raw materials to finished products, and highlights how companies like Bollard Brothers create solutions that protect lives and enhance cityscapes.

Raw Materials: The Foundation of Quality Bollards

The manufacturing of bollards begins with selecting high-quality materials tailored to their intended use—whether for traffic control, pedestrian safety, or high-security applications. Common materials include:

Steel: Stainless steel (often 316-grade for corrosion resistance) or carbon steel is used for its strength and durability, ideal for crash-rated and retractable bollards.

Ferrocast Polyurethane: A polyurethane coating over a steel core, pioneered for harsh environments like coastal areas, offers corrosion resistance and low maintenance.

Concrete: Used for heavy-duty fixed bollards, concrete provides impact resistance and cost-effectiveness for large-scale urban projects.

Cast Iron: Valued for its historical aesthetic and durability, cast iron is common in decorative bollards for heritage sites.

Bio-Polymers: Emerging eco-friendly materials, such as sugar cane-derived polymers, are used for sustainable bollards, reducing environmental impact.

Aluminum: Lightweight and corrosion-resistant, aluminum is used for decorative or temporary bollards in less demanding settings.

Materials are sourced from certified suppliers to ensure consistency. For example, steel must meet ASTM standards for tensile strength, while polyurethane for Ferrocast bollards undergoes testing for UV and abrasion resistance. Bollard Brothers, for instance, sources 316 stainless steel for its coastal installations, ensuring longevity in saline environments.

Design and Engineering: Precision Planning

The design phase is critical to ensure bollards meet functional, aesthetic, and regulatory requirements. Engineers use CAD (Computer-Aided Design) software to create detailed blueprints, specifying dimensions, material thickness, and mechanisms for retractable or smart bollards. Key considerations include:

Purpose: Fixed bollards for permanent barriers, removable for temporary access, or pneumatic/hydraulic for dynamic control.

Impact Resistance: Crash-rated bollards, like those meeting PAS 68 or ASTM F2656, require thicker steel (e.g., 10mm walls) and reinforced bases.

Aesthetics: Decorative bollards may mimic historical designs or incorporate custom engravings, colors, or LED lighting for urban appeal.

Environmental Factors: Coastal or cold climates demand corrosion-resistant or insulated materials.

Prototypes are often 3D-printed or mocked up to test functionality before mass production. Bollard Brothers collaborates with urban planners to design bollards that comply with local safety codes, such as those in Chicago or London, while matching architectural styles.

Manufacturing Process: From Raw Materials to Finished Bollards

The manufacturing process varies by bollard type but generally follows these steps:

1. Material Preparation

Raw materials are cut, shaped, and treated to meet specifications:

Steel: Cut into cylinders or plates using laser or plasma cutters for precision. Stainless steel is polished or coated to prevent rust.

Concrete: Mixed with aggregates and poured into molds, often reinforced with rebar for added strength.

Polyurethane: Liquid polyurethane is prepared for casting around steel cores, as in Ferrocast bollards, ensuring a seamless, durable finish.

2. Forming and Assembly

Fixed Bollards: Steel or cast-iron pipes are welded or cast into cylindrical shapes. Concrete bollards are poured into molds and cured for 28 days to achieve maximum strength.

Retractable Pneumatic Bollards: Internal pistons and gas springs are assembled within a steel casing. Air compressors are integrated for raising/lowering mechanisms, tested for speed (e.g., 3-5 seconds per cycle).

Decorative Bollards: Ornate patterns or motifs are cast or engraved, often using sand-casting for cast iron or injection molding for polyurethane.

Smart Bollards: Sensors, LEDs, or solar panels are embedded during assembly, with wiring protected by waterproof seals.

Bollard Brothers employs automated welding for precision and consistency, ensuring joints can withstand impacts of up to 7,500 pounds at 50 mph for crash-rated models.

3. Surface Treatment and Finishing

Coatings: Steel bollards are galvanized or powder-coated to resist corrosion. Polyurethane bollards receive a two-part gloss paint for UV and abrasion resistance.

Polishing: Stainless steel is polished to a mirror finish for aesthetic appeal, common in high-end commercial settings.

Customization: Bollards may be painted in custom colors, engraved with logos, or fitted with reflective bands for visibility.

4. Quality Control and Testing

Each bollard undergoes rigorous testing:

Impact Testing: Crash-rated bollards are tested against standards like ASTM F2656, simulating vehicle impacts to ensure structural integrity.

Environmental Testing: Bollards are exposed to salt spray, UV light, or extreme temperatures to verify durability.

Functionality Testing: Retractable bollards are cycled thousands of times to confirm reliability. Smart bollards are tested for sensor accuracy and connectivity.

Bollard Brothers, for example, conducts 10,000-cycle tests on pneumatic bollards to guarantee long-term performance, with a failure rate below 0.5%.

5. Packaging and Distribution

Finished bollards are packaged to prevent damage during transport, often with protective foam or crates. They are shipped to clients or distributors, accompanied by installation guides. Bollard Brothers includes detailed manuals for root-fixed or removable installations, ensuring compliance with local regulations.

Innovations in Bollard Manufacturing

Recent advancements have transformed bollard production:

Automation: CNC machines and robotic welding improve precision and reduce production time, lowering costs for high-volume orders.

Sustainable Practices: Manufacturers like Bollard Brothers use recycled steel and bio-polymers, reducing carbon footprints. Their 2024 initiative cut material waste by 15% through optimized cutting techniques.

Smart Technology: Integration of IoT sensors and AI in bollards, like Bollard Brothers’ SmartShield series, requires specialized assembly lines for embedding electronics without compromising structural strength.

Modular Designs: Prefabricated components allow faster customization, enabling clients to choose features like LED lighting or retractable mechanisms during ordering.

Applications and Impact

Manufactured bollards serve diverse purposes:

Public Spaces: Fixed concrete bollards protect pedestrian zones in cities like New York, reducing accidents by 12% in high-traffic areas (2024 data).

Private Properties: Stainless steel pneumatic bollards secure retail entrances, deterring ram-raiding with zero incidents reported in Bollard Brothers’ 2025 commercial projects.

Heritage Sites: Decorative cast-iron bollards enhance aesthetic appeal in historic districts, boosting tourism while ensuring safety.

Challenges in Bollard Manufacturing

Manufacturing bollards is not without challenges:

Cost: High-security or smart bollards require expensive materials and complex assembly, with costs ranging from $1,000 for basic models to $15,000 for crash-rated pneumatic units.

Customization: Balancing client-specific designs with mass-production efficiency demands flexible production lines.

Sustainability: While eco-friendly materials are gaining traction, scaling their use without compromising strength remains a hurdle.

Bollard Brothers addresses these by offering modular designs and investing in green manufacturing, such as solar-powered production facilities, which cut energy costs by 20% in 2025.

Future of Bollard Manufacturing

The future of bollard manufacturing lies in sustainability and smart integration. By 2030, industry experts predict 60% of bollards will use recycled or bio-based materials, driven by environmental regulations. Smart bollards with 5G connectivity and AI analytics will become standard, enabling real-time traffic and security monitoring. Bollard Brothers is pioneering this shift with plans to launch a fully recyclable pneumatic bollard line by 2027, reducing environmental impact while maintaining crash-rated performance.

Conclusion

The manufacturing of bollards is a blend of engineering precision, material innovation, and design creativity. From selecting durable steel and eco-friendly polymers to integrating smart technology, manufacturers like Bollard Brothers craft bollards that protect lives and enhance urban spaces. As cities evolve, the bollard industry will continue to innovate, ensuring safety and style go hand in hand. Ready to secure your space with expertly crafted bollards? Contact Bollard Brothers for a free quote on custom solutions tailored to your needs.